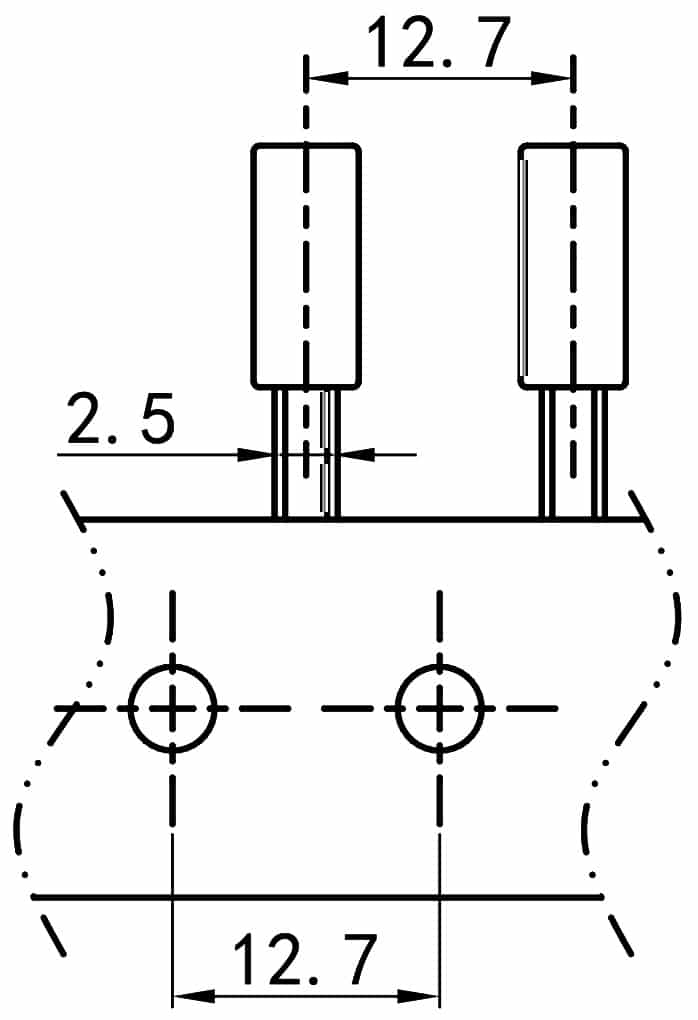

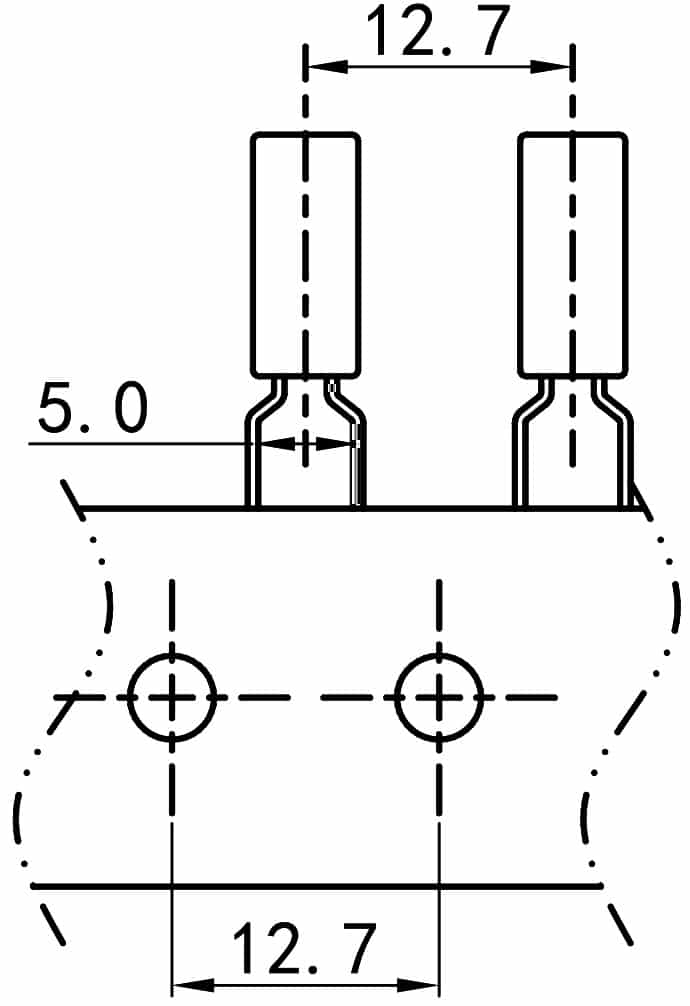

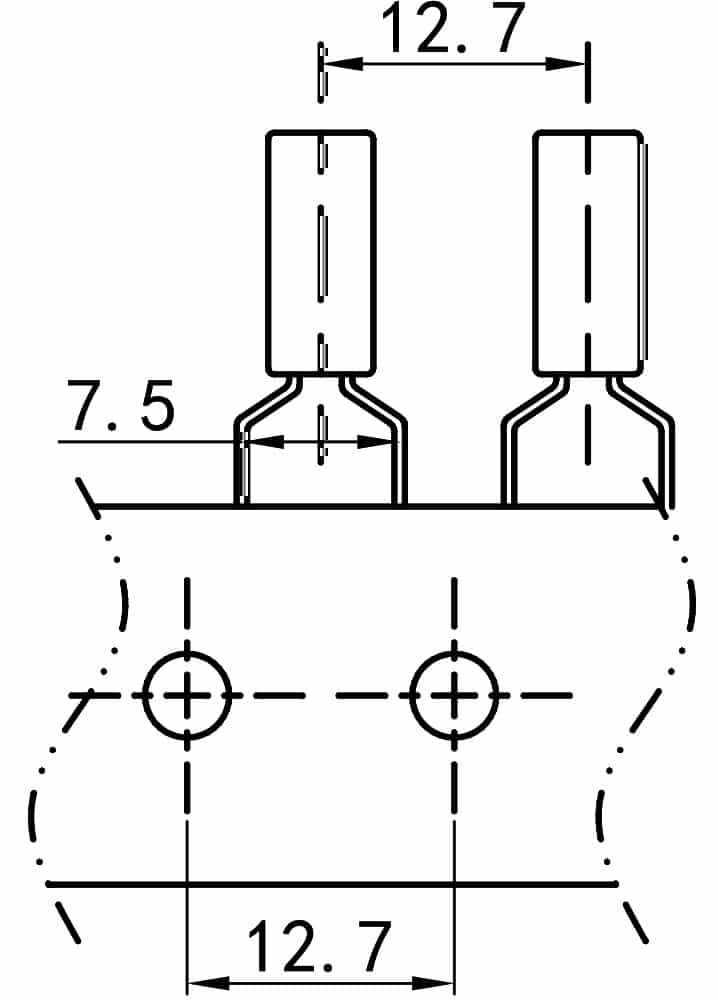

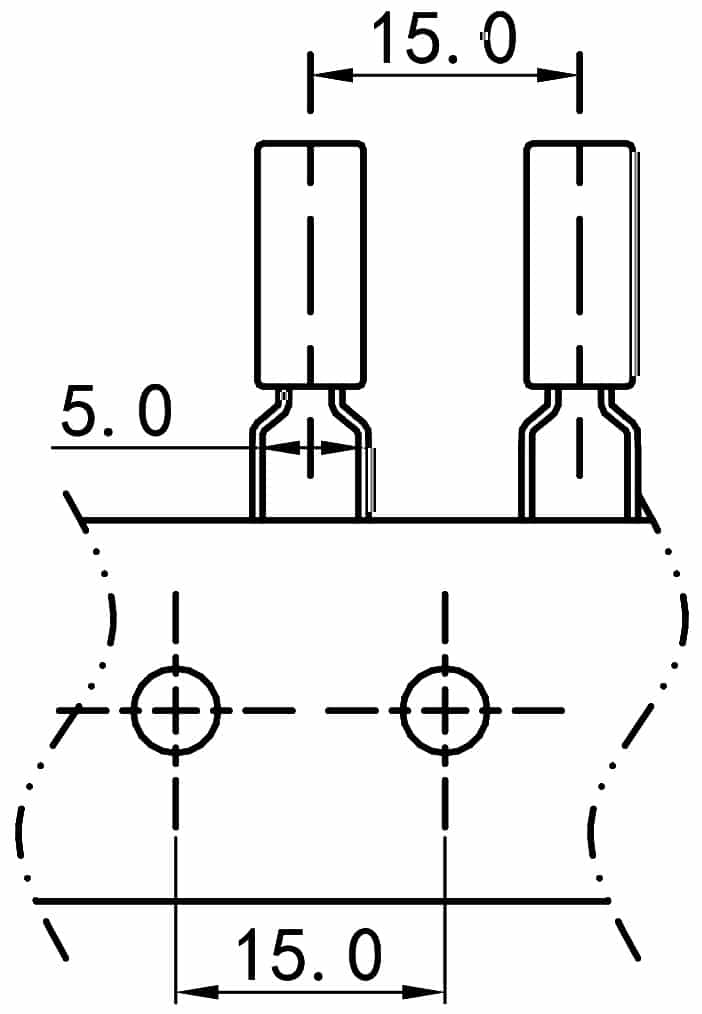

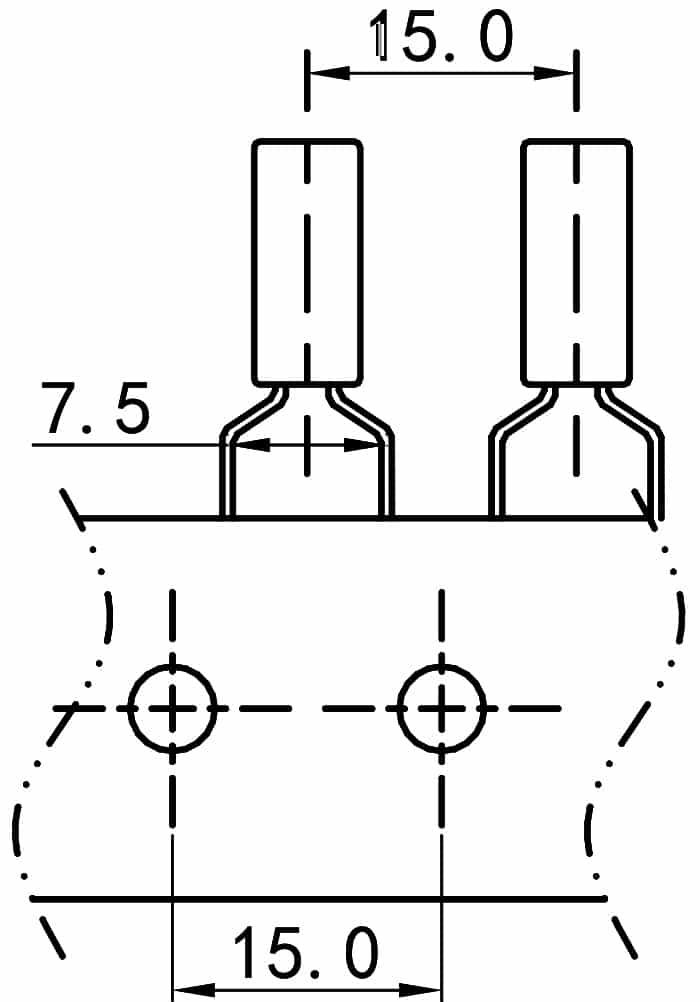

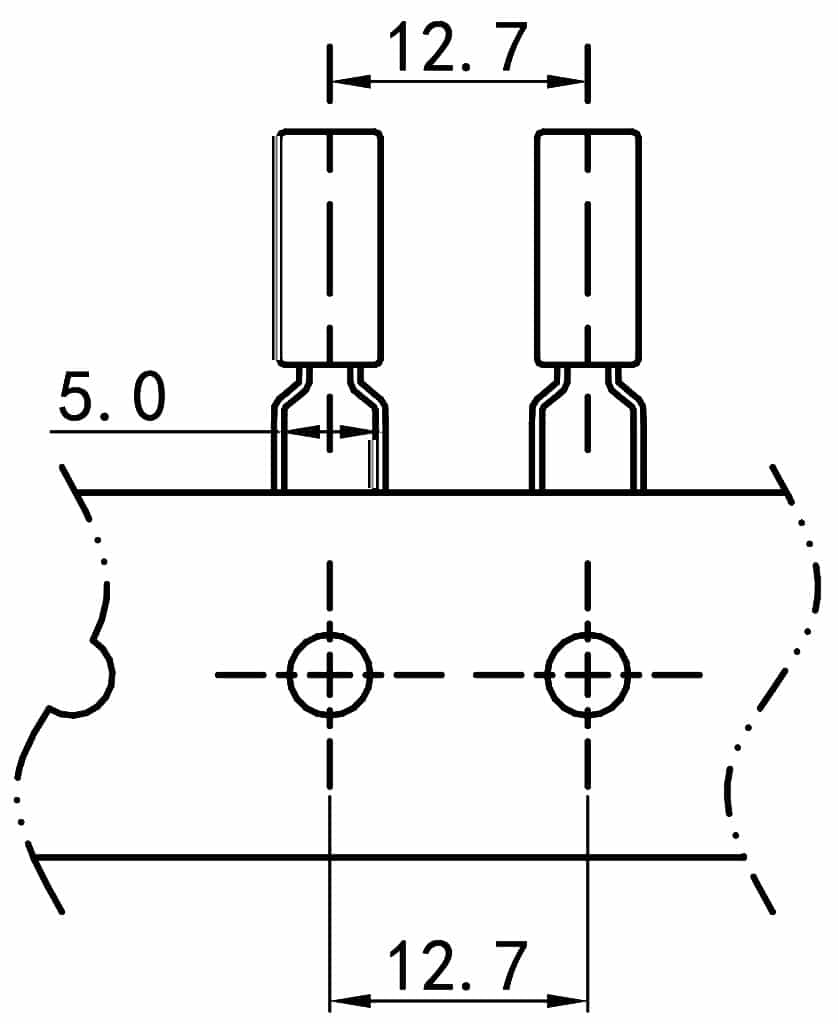

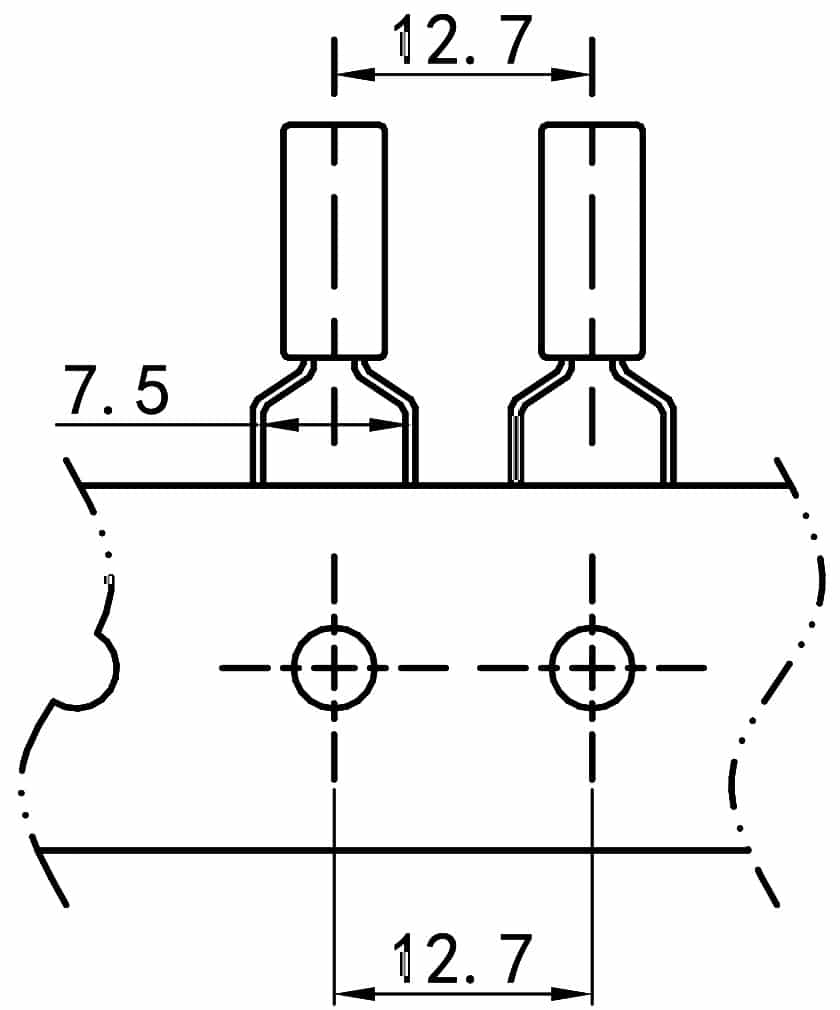

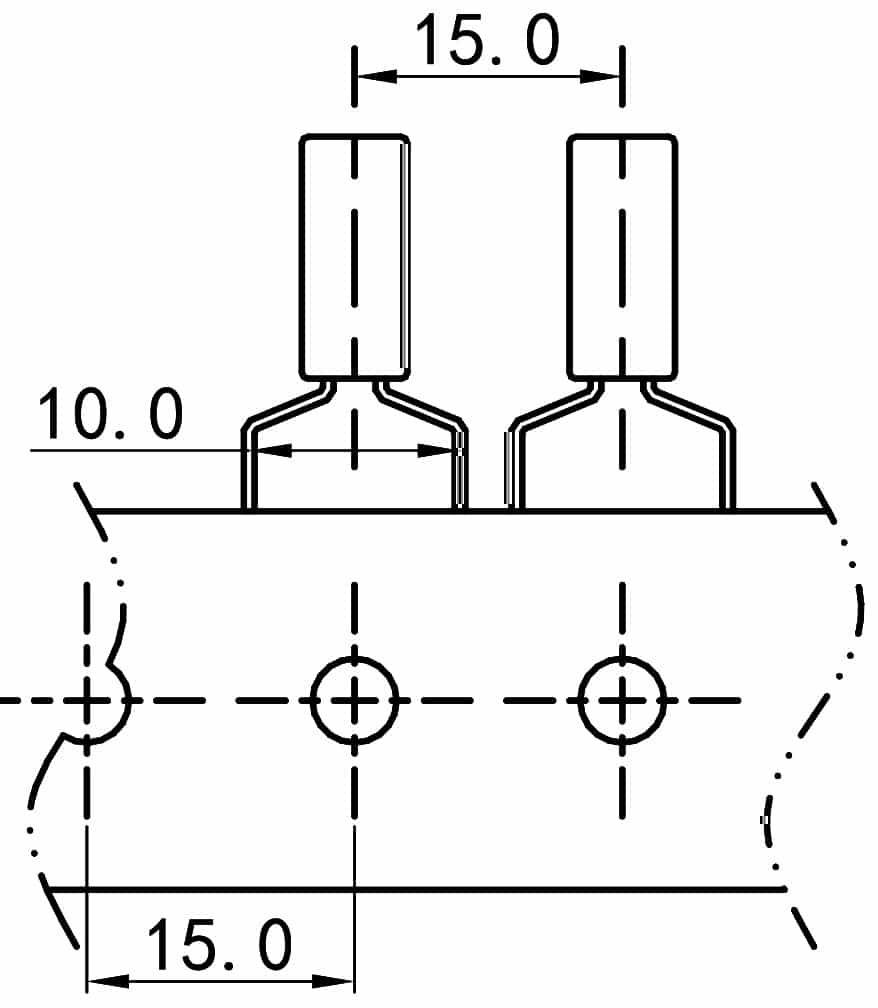

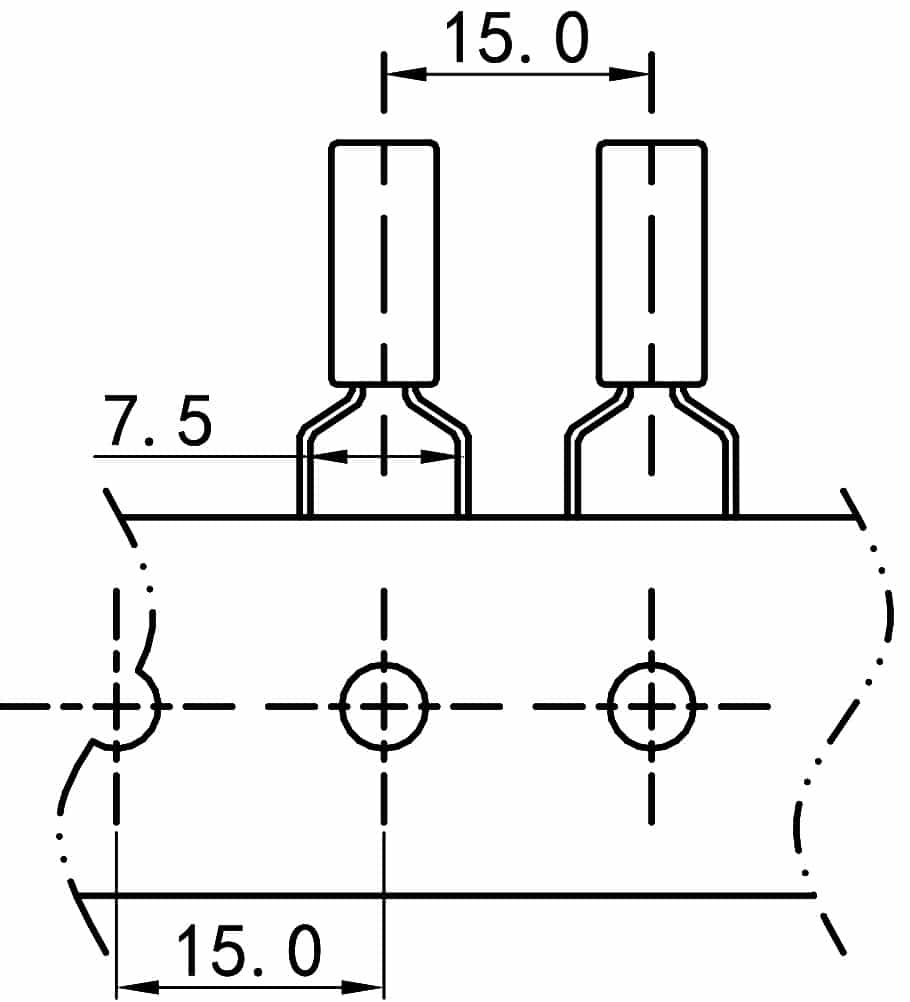

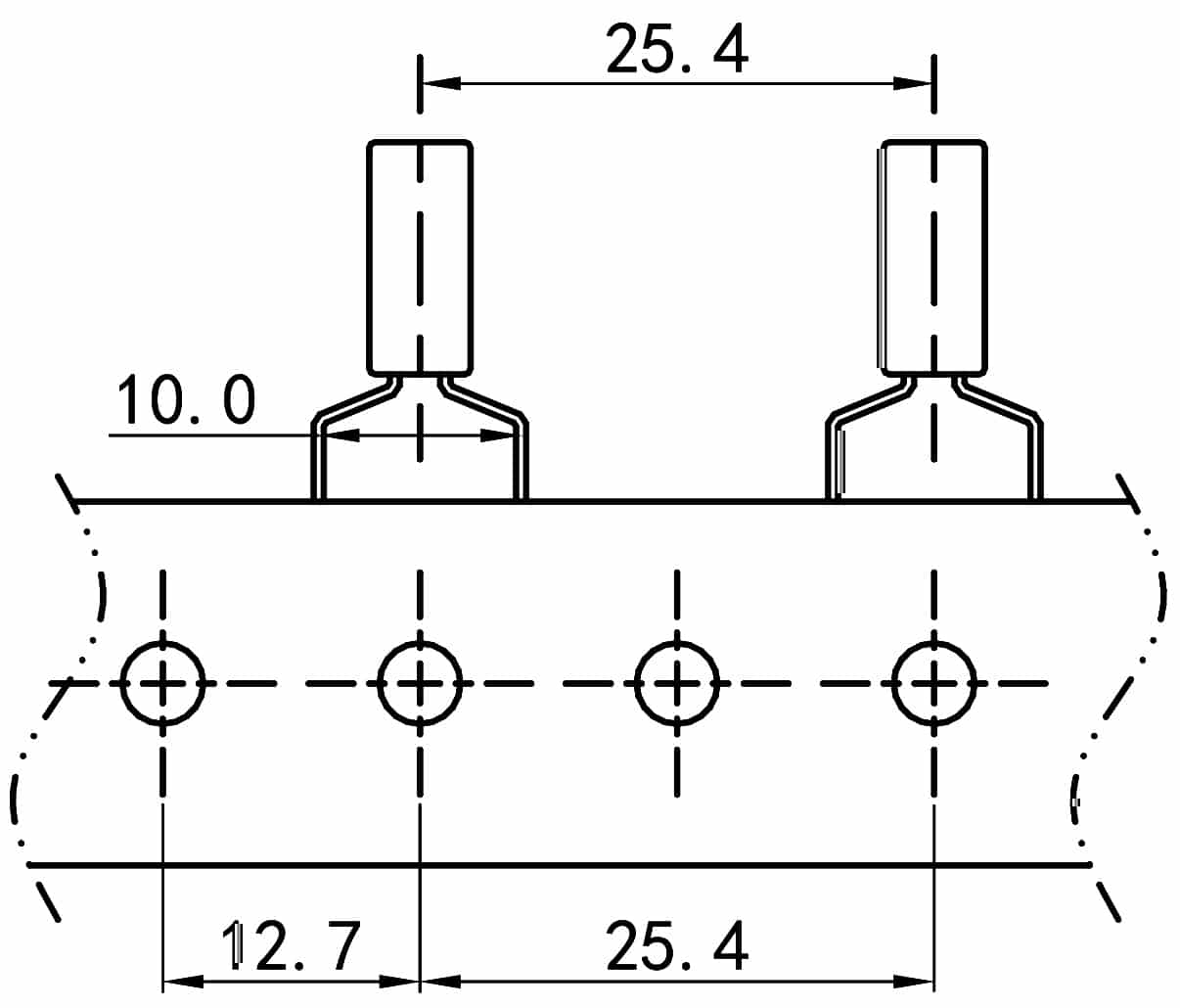

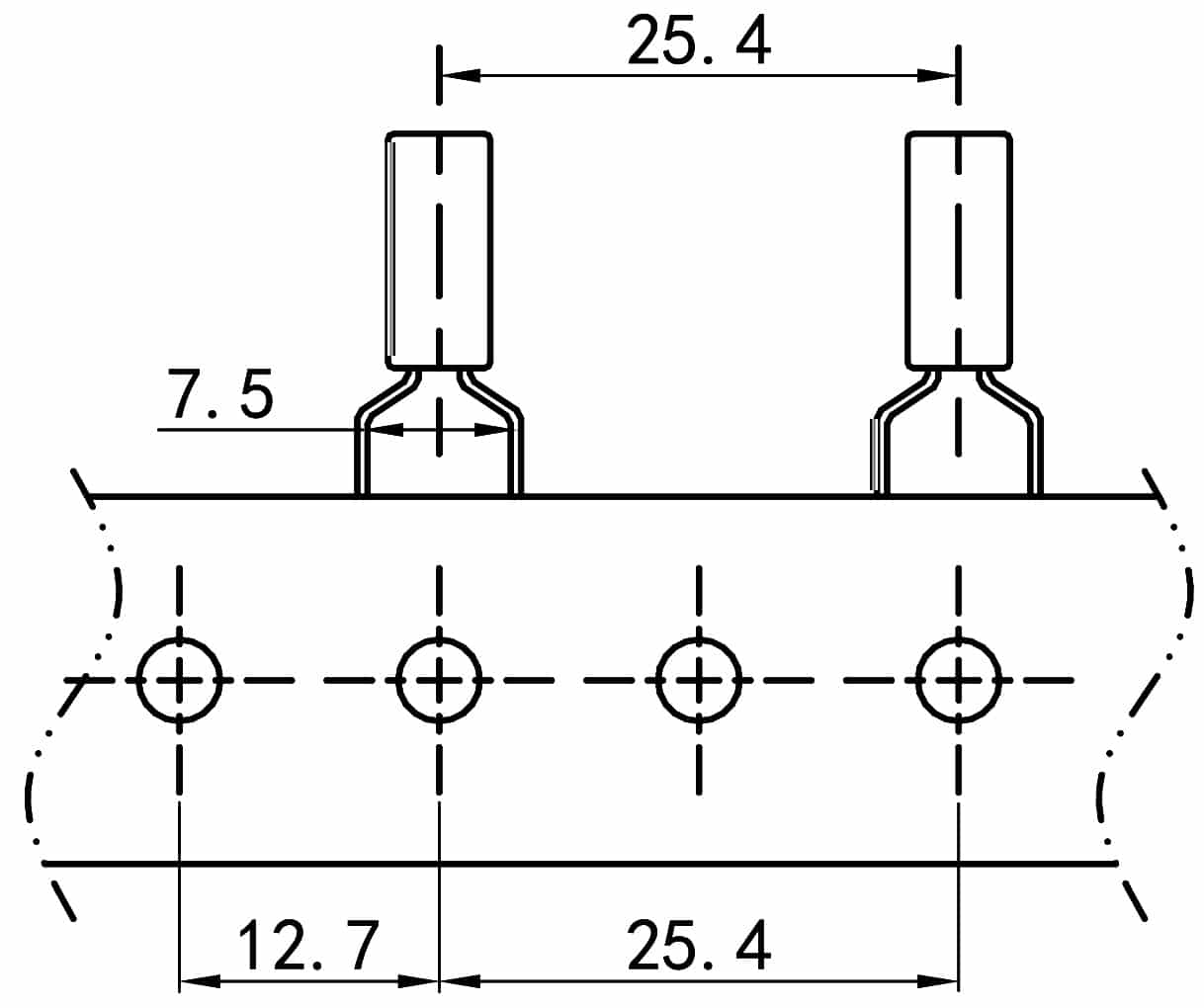

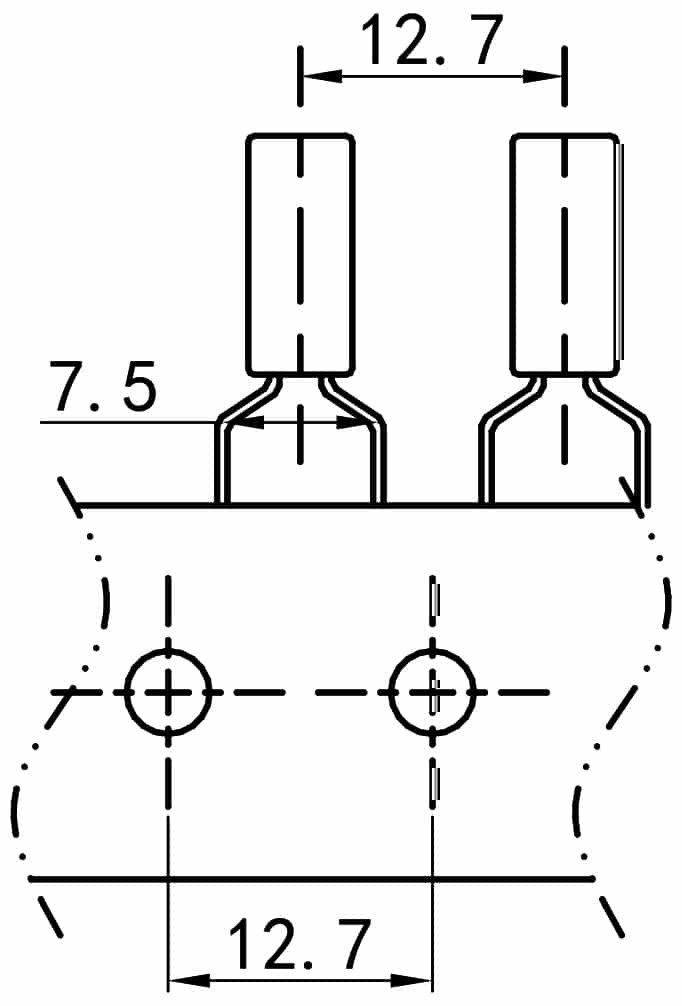

Reference data for feeder selection: 1. Taping hole spacing, 2. Component foot span, 3. Relative position of the component and the paper tape hole core. (The following listed parameters are made in millimeters (mm))

| numbering | mark | Taping hole spacing | Line foot span | Applicable taping material legend |

| NB16812750 普通Feeder | 无标记 None | 12.7 | 2.5 5.0 7.5 |    |

| NB16815075 绿色Feeder | 绿色 Green | 15.0 | 5.0 7.5 |   |

| NB16812775S 黄色Feeder | 黄色 Yellow | 12.7 | 5.0 7.5 |   |

| NB16815010 白色Feeder | 白色 White | 15.0 | 7.5 10.0 |   |

| NB16825410 蓝色Feeder | 蓝色 Blue | 25.4 | 7.5 10.0 |   |

| NB16812775 红色Feeder | 红色 Red | 12.7 | 7.5 |  |

Vertical inserter feeders are specialized devices used in automated assembly lines (particularly in PCB manufacturing) to handle and present components for insertion or placement. Their “vertical” orientation saves space compared to horizontal feeders. Here’s a breakdown of categories and key selection factors:

I. Vertical Inserter Feeder Categories (Based on Component Type & Feeding Mechanism):

- Tape Feeders (Reel-to-Reel):

- Description: Most common. Handle components supplied on embossed plastic or paper carrier tapes wound on reels.

- Mechanism: Tape is advanced incrementally (pneumatically or electrically). A cover tape is peeled back, exposing the component pocket. A pickup head (of the inserter/placement machine) removes the component.

- Sub-Types: Standard pitch (e.g., 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm), metric (e.g., 4mm, 12mm), Cut Tape (shorter lengths).

- Components: Resistors, capacitors, ICs (SOP, QFP, etc.), diodes, small connectors, transformers, relays – essentially any component supplied on tape.

- Stick (Tube) Feeders:

- Description: Handle components supplied in straight plastic tubes (“sticks”).

- Mechanism: Tubes are loaded vertically. Components are gravity-fed down the tube. A shuttle mechanism or escapement presents one component at a time at the pickup position. An agitator may prevent jamming.

- Components: Taller components unsuitable for tape, some ICs (DIPs), connectors, electrolytic capacitors, crystals, switches.

- Tray Feeders (Matrix Trays):

- Description: Handle components supplied in matrix trays (JEDEC standard or custom).

- Mechanism: Trays are stacked vertically on a lift mechanism. The lift indexes each tray to the correct height. An X-Y gantry (either part of the feeder or the inserter machine) moves over the tray to pick components sequentially.

- Components: Large, heavy, sensitive, or odd-shaped components (BGAs, large QFPs, connectors, modules, RF shields, large capacitors, transformers, sensitive MEMS devices).

- Vibratory Bowl Feeders (Less Common for Inserters):

- Description: Use vibration and tooling tracks to orient and feed bulk components.

- Mechanism: Components are loaded into the bowl. Vibration moves them up the spiral track past orientation tooling, presenting them correctly at the exit chute.

- Components: Small bulk parts like pins, jumpers, specific connectors, or odd-form components difficult for tape/stick/tray. Often used for non-standard insertion tasks.

- Bulk Feeders (e.g., Solder Ball Feeders):

- Description: Handle very small, loose components (like solder balls for BGA assembly).

- Mechanism: Use precise dispensing mechanisms (vibration, vacuum, rotating disks) to present a controlled quantity of components.

- Components: Primarily solder spheres for BGA/CSP assembly.

II. Vertical Inserter Feeder Selection Factors:

Choosing the right feeder involves careful consideration of these key factors:

- Component Characteristics:

- Type & Form Factor: What is the component? (Resistor, IC, connector, transformer, etc.) Dictates the primary category (Tape, Stick, Tray).

- Size & Dimensions: Length, Width, Height, Weight. Must fit within the feeder’s specifications.

- Packaging: How is the component supplied? (Reel, Tube, Tray, Bulk). This directly determines the feeder type needed.

- Fragility/Delicate Features: Sensitive components (BGAs, MEMS) often require gentle tray handling.

- Production Requirements:

- Throughput (Units per Hour): How fast does the feeder need to present components? High-speed lines need high-speed feeders (especially tape).

- Changeover Frequency: How often will feeder types/components change? Consider quick-change systems and feeder compatibility standards (SMEMA, Hermes).

- Line Compatibility: Must interface correctly with the specific Vertical Inserter/Placement Machine (electrical, mechanical, communication protocols).

- Number of Unique Components: Determines how many feeder slots/types are needed on the line.

- Feeder Capabilities & Specifications:

- Feeder Type: Match to component packaging (see Categories above).

- Pitch/Width: For tape feeders, must match the tape pitch (e.g., 8mm, 12mm). For trays, must handle the tray size (e.g., JEDEC 4×4″).

- Component Size Range: Min/Max LxWxH and weight the feeder can handle.

- Feeding Speed/Accuracy: Critical for high-speed placement accuracy.

- Reliability & Uptime: Low jam rates, robust design, easy maintenance.

- Connectivity & Control: Compatibility with machine control systems (I/O, serial, Ethernet).

- Footprint: Physical size on the machine.

- Operational Factors:

- Ease of Loading/Setup: How quickly and easily can operators load new reels/tubes/trays?

- Ease of Programming: Setting up component offsets and feeder parameters in the machine software.

- Maintenance Requirements: Cleaning, lubrication, part replacement needs.

- Vision Requirements: Does the component require machine vision for accurate pickup? Feeder design shouldn’t obstruct vision.

- Cost Considerations:

- Initial Investment: Cost of the feeder units themselves.

- Cost of Ownership: Maintenance costs, consumables (e.g., peel blades for tape feeders), downtime costs.

- Scalability/Flexibility: Can the feeder handle future component needs? Is it part of a modular system?

Selection Process Summary:

- Identify Components: List all components requiring feeding, noting their packaging, dimensions, and fragility.

- Match Packaging to Feeder Type: Tape -> Tape Feeder, Tube -> Stick Feeder, Tray -> Tray Feeder, Bulk -> Bowl/Bulk Feeder.

- Check Specifications: Ensure feeder model supports the specific component dimensions, weight, pitch, and required speed.

- Verify Machine Compatibility: Confirm mechanical mounting, electrical connection, and communication protocol compatibility with your inserter/placer.

- Evaluate Throughput & Changeover: Ensure feeders can meet cycle time demands and support your production schedule’s changeover needs.

- Consider Operational Factors: Prioritize ease of use, reliability, and maintainability.

- Assess Cost vs. Value: Balance initial cost with long-term reliability, uptime, and flexibility.

By systematically evaluating these categories and selection factors, you can choose the optimal vertical inserter feeders for your specific automated assembly application, maximizing efficiency, yield, and uptime.