Axial automatic insertion machine NB168A is used to accurately insert axial leads and axial electronic components into pre-drilled holes in printed circuit boards, effectively improving the assembly production efficiency of PCBA; Reduce recruitment risks and labor costs.

Exterior picture of the axial automatic insertion machine NB168A

Production video of the axial automatic insertion machine NB168A

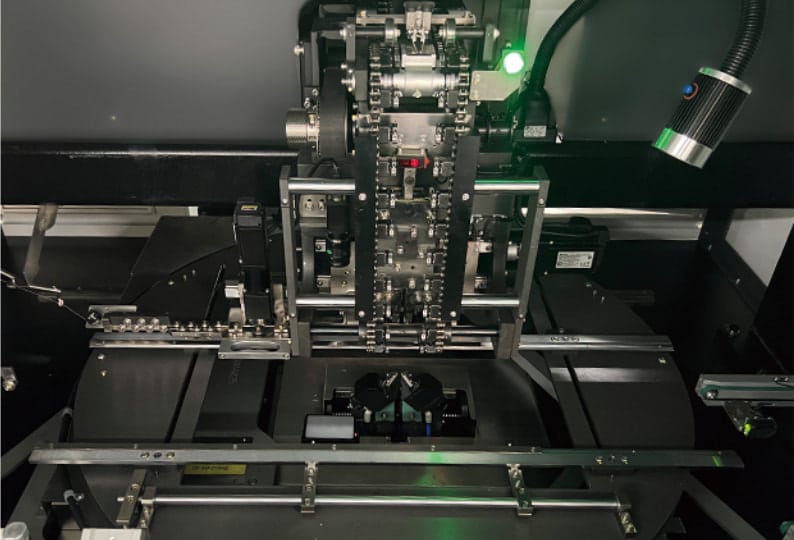

Partial detail image of the axial automatic insertion machine NB168A

Picture of the insertion system of the axial automatic insertion machine NB168A

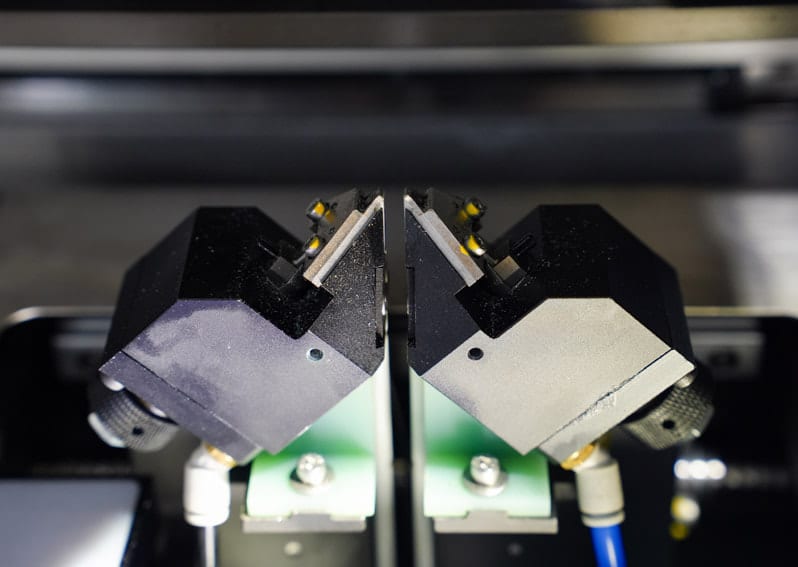

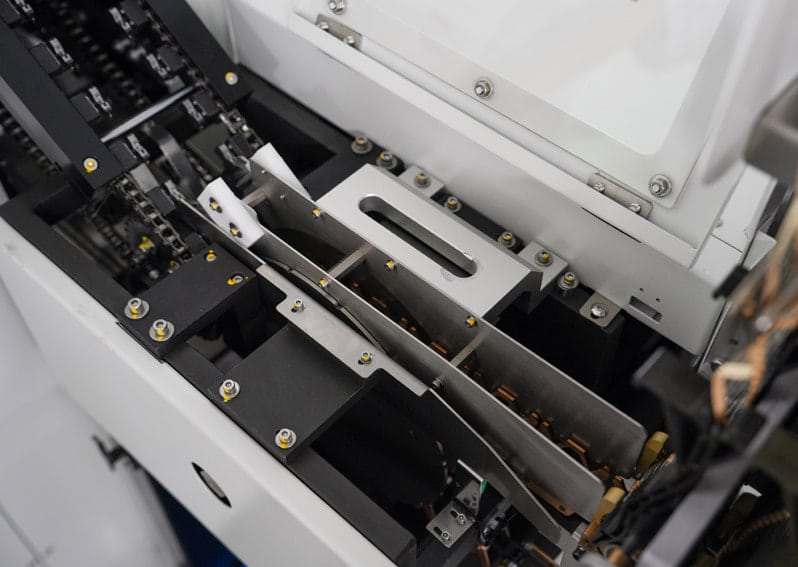

Picture of the feeding bending mechanism of the axial automatic insertion machine NB168A

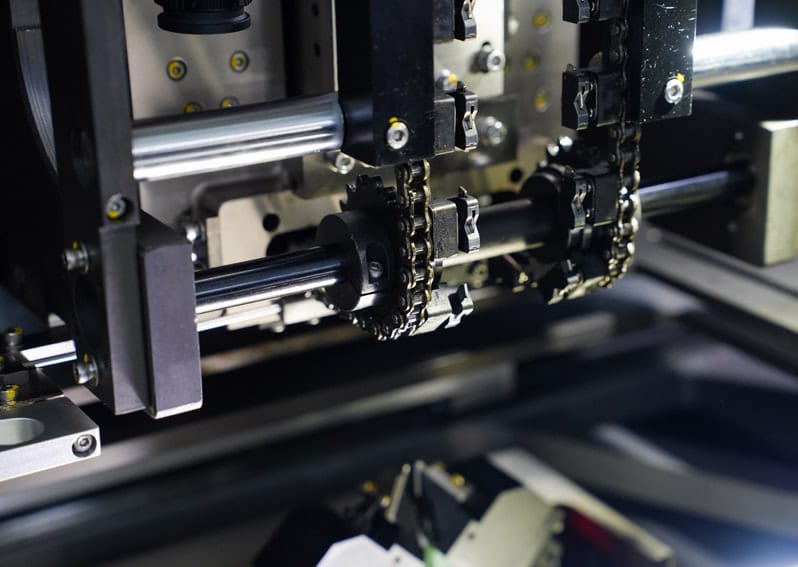

Picture of the feeding mechanism of the axial automatic insertion machine NB168A

Picture of the bending system of the axial automatic insertion machine NB168A

Visual positioning image of the axial automatic insertion machine NB168A

Picture of the shaping mechanism of the axial automatic insertion machine NB168A

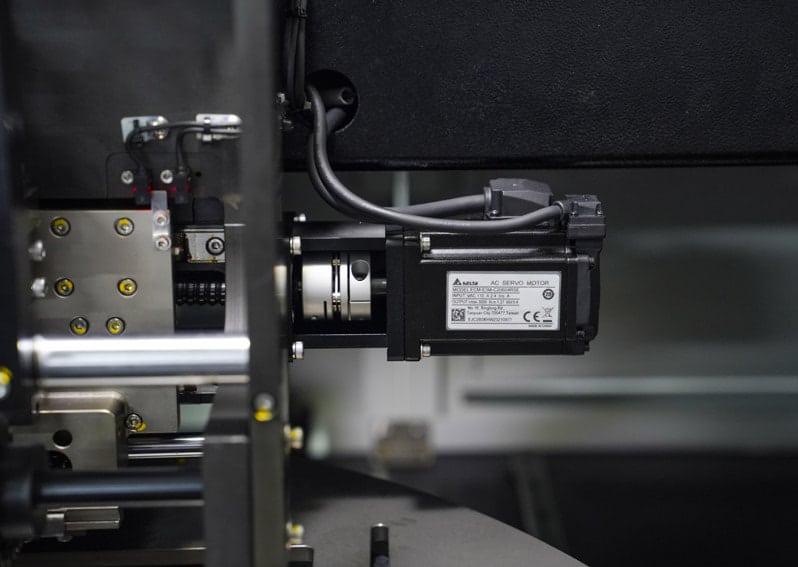

Picture of the feeding motor of the axial automatic insertion machine NB168A

Picture of material transfer track of axial automatic insertion machine NB168A

Axial automatic insertion machine NB168A produces video at any angle

Technical parameters of the axial automatic insertion machine NB168A

| item/项目 | Content | 内容 |

|---|---|---|

| Rated voltage:3-phase380V±20V | 额定电压:3相380V±20V | |

| 电源Power Supply | Frequency:50/60Hz | 频率:50/60Hz |

| Rated capacity: Approx.3.5KVA | 额定功率:约3.5KVA | |

| 空气源Air supply | 供给气压:Min.0.45 Mpa-Max.0.8Mpa(运转气压0.45MPa~0.5MPa) | Supplied air pressure: Min.0.45 Mpa-Max.0.8Mpa (Operation air pressure0.45MPa~0.5MPa) |

| 供给空气量:约110L/min.(A.N.R) | Supplied air mass:Approx.110L/min.(A.N.R) | |

| 插入跨距 Insert span | 2P:2.5mm/5.0mm; :3.5P:2.5mm/5.0mm/3.5mm; 3P:2.5mm/5.0mm/7.5mm; 4P/T4P:2.5mm/5.0mm/7.5mm/10.0mm 可选 | |

| 设备尺寸Dimensions | L:2140mm,W:1760mm,H:1600mm(不包信号塔料架) | L:2140mm,W:1760mm,H:1600mm(Not including signal towe) |

| 质 量 M a s s | 主机重量: 约2,200kg(仅主机) | Host weight: Approx.2,200kg(Main body only) |

| 环境条件 Environmental requirements | 温度:20℃±10℃ | |

| 通过LCD彩色触摸屏进行对话式的操作。 | Interactive operation via color LCD touch screen. | |

| 操作部 Operating controls | 输入和输出功能:U盘 插槽标准配置 | I/O functions:USB Slot standard equipment |

| 通信功能:LAN通信(TCP/IP) | Communication:LAN communication(TCP/IP) | |

| 外观颜色Color | 标准颜色:白色+蓝色 | Standard color:White+blue |

| 插入节拍(速度) Insertion tact time | UPH: 21500点/小时 最高速度节拍时间约 0.168秒/点(0.2、0.25、0.30s/点,可切换) | UPH: 21500 points/hour Max.tact time:Approx.0.14s/point (0.20,0.25,0.30s/point changeable) |

| 高度:最大23mm(定制规格可达26mm) | Heigh:Max23mm(Special specification up to 26mm) | |

| 适用元件 Applicable components | 直径:最大 13mm | Diameter: D=Max 13mm |

| 电阻、电解电容器、陶瓷电容器、LED 晶体管、过滤器电阻网络 | Resistors, electrolytic capacitors, ceramic capacitors, LEDs transistors, filters and resistor networks | |

| 基 板 更 换 时 间 PCB replacement time | 基板交换装载时间约3-4秒 | Approx.3~4 seconds |

| 基板尺寸:最小 50mm×50mm~最大 508mm×381mm | Dimensions:Min . 50mm×50mm~Max . 508mm×381mm | |

| 可插入范围:最小50mmx40mm~最大 500mm×375mm | Allowable insertion area:Min.50mmx40mm~Max.500mm×375mm | |

| 基板厚度: 1.6mm±0.15mm(标准可应对)最小0.6mm~最大2.0mm(选配) | Thickness:1.6mm±0.15mm(for tandard specification) Min.0.6mm~Max2.0mm(Special spectica) | |

| 适用基板 Applicable PCB | 基板重量:元件插入完毕的基板重量在1kg以内 | Mass:Max.1kg per board including inserted components. |

| 流向:右→左(标准)、左→右(选配) | Flow direction: right→left(Standard)、left→right(Option) | |

| 基板规正方法:销规正或者夹边定位 | Board positioning method:Pin positioning or Edge positioning | |

| 基板传输: 单板传输(标准) 双板传输(选配) | Board transfer: Single PCB transfer(Standard) Double PCB transfer(Special specification) | |

| 插入方向Insertion direction | 0°-360°方向(以1°递增) | 360° degrees by1° degree |

| 砧台Anvil | 弯脚角度 30°±15°剪脚长度1.2~1.8mm | Clinch Angle 30°±15°Cut Clinch Lungth1.2-1.8mm |

| 元件种类 No.of componentinputs | 可搭载40种类 | 40 inputs |

| 控制系统Control system | 微机方式 | Microcomputer system |

| X-Y轴:绝对坐标指令 | X-Y axes: Absolute coordinate commands | |

| 插入跨距:绝对指令 | Insertion pitch:Absolute commands | |

| 元件供给部:飞达号指令 | Component feeder:Feeder number designation | |

| X-Y工作台移动单位Least command increment of X-Y table | 0.01mm/脉冲 | 0.01mm/Pulse |

| 噪音水平 Noise Level | 约65 分贝 | Approx 65 db |

| 程序 Program | 主体内置式闪存器程序数量为2000+个 | Built-in flash memory 2000+prograrms |

| U盘根据卡的容量 | USB Disk Depending on USB disk memory | |

| 显示灯 Indication light | 信号塔(三色灯上起红、黄、绿) | Signal tower (3 lamps, op to bottom: red/yellow/green) |

| 孔位置补正方式 Hole position offset | 根据插入位置对所有孔识别结果(XY补正和Φ补正),算出最佳的插入位置,进行位置补正 | Determines optimum insertion positions based on the recognition of all insertion positions to make positional corrections (XY Correction and Φ Correction.). |

| 补插方式Recovery | 自动补插/手动机器补插(补插时间约为12秒) | Auto recovery/Auto recovery(Estimated Auto-recovery Time Approx.12s) |

| 自行诊断功能Self-diagnosis function | 当设备运行的状态下发生不良时,不良状况及故障信息显示在人机画面,并提示应对措施 | Presents on the color LCD the machine status when the power is ON and situation of any troubles occurred, as well as countermeasures against the troubles |

The above content is the relevant information of the axial automatic insertion machine NB168A, please contact online customer service for more details